Ukukhetha okubanzi kunyepassivation of steel stainless, ukususa amabala e-oyile ahlukeneyo, umhlwa, ulusu lwe-oxide, amalungu e-solder kunye nolunye ukungcola.Emva konyango, umphezulu wesilivere omhlophe, uphucula kakhulu ukuxhathisa kwe-corrosion yensimbi engenasici, efanelekileyo kwiindawo ezahlukeneyo zentsimbi, iipleyiti kunye nezixhobo.

Kulula ukuyisebenzisa, kulula ukuyisebenzisa, inoqoqosho kwaye iyasebenza, kunye nokongezwa kwe-corrosion inhibitors esebenza kakuhle kakhulu ukuthintela ukubola kwesinyithi kunye ne-hydrogen embrittlement, kunye nokucinezela ukuveliswa kwenkungu ye-asidi.Ngokukodwa ezifanelekileyo kwii-workpieces ezincinci kunye eziyinkimbinkimbi, ezingafanelekanga ukugquma, ziphakamileyo kwiimveliso ezifanayo kwiimarike.

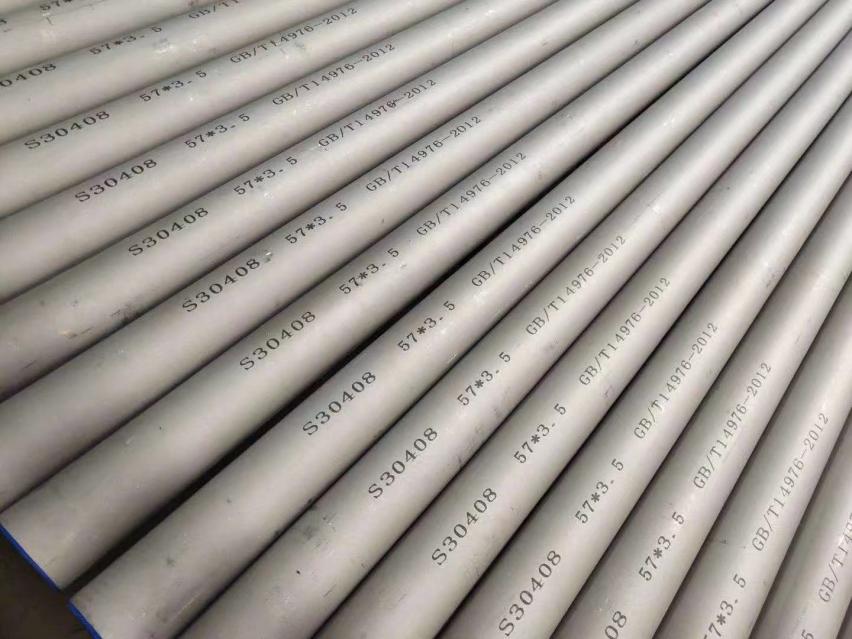

Ngokobunzima bezinto zensimbi ezingenasici kunye nesikali se-oxide, isisombululo sokuqala singasetyenziselwa okanye sihlanjululwe ngamanzi kumlinganiselo we-1: 1: 1-4 ngaphambi kokusetyenziswa;I-Ferrite, i-Martensite kunye ne-austenitic stainless steel kunye nomxholo we-nickel ophantsi (ofana ne-420.430.200.201.202.300. Emva kwe-dilution, i-austenitic stainless steel kunye nomxholo we-nickel ephezulu (njenge-304), i-321.316.316L; isisombululo se-stocked siya kuba njalo.Ngokubanzi, emva kobushushu obuqhelekileyo okanye ukufudumeza ukuya kwi-50 ~ 60 ℃, cwilisa imizuzu emi-3-20 okanye ngaphezulu (ixesha elithile kunye nobushushu liya kumiselwa ngumsebenzisi ngokwemeko yovavanyo) de ukungcola komphezulu kususwe ngokupheleleyo, kumhlophe ngokulinganayo. , ukwenza iyunifomu kunye nefilimu eshinyeneyo yokwenziwa.Emva konyango, yikhuphe, uyihlambe ngamanzi acocekileyo, kwaye unciphise ngamanzi ane-alkaline okanye iLimewater.

Imfuneko yokukhetha insimbi engenasici kunye ne-passivation

Intsimbi engatyiwayo inokumelana nokugqwala okuhle, ukumelana nobushushu obuphezulu be-oxidation, ukusebenza kakuhle kobushushu obuphantsi, kunye nepropathi elungileyo yoomatshini kunye ne-R.Ngoko ke, isetyenziswa kakhulu kwiikhemikhali, i-petroleum, amandla, ubunjineli beNyukliya, i-aerospace, i-marine, amayeza, imboni yokukhanya, i-textile kunye namanye amacandelo.Injongo yayo ephambili kukuthintela ukubola kunye nokugqwala.Ukuxhatshazwa kwe-corrosion of steel stainless ikakhulu kuxhomekeke kwifilimu ye-surface passivation.Ukuba ifilimu ayiphelelanga okanye inesiphene, isinyithi esingenasici siya kuhlala sidliwe.I-Acid pickling kunye ne-passivation ziqhelekileyo zisetyenziselwa ubunjineli ukunyusa ukuxhathisa ukubola kwensimbi engenasici.Ngexesha lokubunjwa, indibano, i-welding, i-weld inspection (njengokubona impazamo, uvavanyo loxinzelelo), kunye nenkqubo yokumakisha ukwakhiwa kwezixhobo zensimbi engenasici kunye namacandelo, amabala e-oyile angaphezulu, i-rust, i-non-metallic dirt, i-metal melting point, i-painting point, ipeyinti, i-welding slag, kunye ne-splashes inokuchaphazela umgangatho ophezulu wezixhobo zetsimbi kunye namacandelo, yonakalisa ifilimu ye-oxide ebusweni bayo, inciphise ukubola okubanzi kunye nendawo yentsimbi (kubandakanywa ne-pitting corrosion), i-gap corrosion), kwaye ikhokelela kuxinzelelo lwe-corrosion cracking. .

Ukucoca umphezulu wensimbi engenasici, i-pickling kunye ne-passivation ayikwazi nje ukuphucula ukunyanzeliswa kwe-corrosion ukuya kwinqanaba eliphezulu, kodwa kunye nokuthintela ukungcoliswa kwemveliso kunye nokufezekisa iziphumo zobuhle.I-GBl50-1998 "Ii-Steel Pressure Vessels" ichaza ukuba umphezulu wezikhongozeli ezenziwe ngensimbi engenasici kunye neeplate zetsimbi ezidibeneyo kufuneka zicocwe kwaye zigqithiswe.Lo mmiselo uyasebenza kwiinqanawa zoxinzelelo ezisetyenziswa kwishishini lepetrochemical.Njengoko ezi zixhobo zisetyenziselwa kwiimeko apho zidibana ngokuthe ngqo kunye neendaba ezitshabalalisayo, kuyimfuneko ukucebisa i-asidi pickling kunye nokugqithisa ukusuka kumbono wokuqinisekisa ukuxhathisa ukubola kunye nokuxhathisa ukubola.Kwamanye amacandelo amashishini, ukuba akusiyo ukuthintela ukubola, kusekelwe kuphela kwiimfuno zokucoceka kunye ne-aesthetics, ngelixa insimbi engenasici ayifuni i-pickling kunye ne-passivation.Kodwa i-welds yezixhobo zensimbi ezingenasici nazo zifuna i-pickling kunye ne-passivation Kwezinye izixhobo zekhemikhali ezineemfuno eziqinileyo zokusetyenziswa, ngaphezu kokucoca i-asidi kunye nokugqithisa, i-high purity medium iya kusetyenziselwa ukucoceka kokugqibela okanye ukucoca ngomatshini, ukugqiba i-chemistry kunye ne-Electropolishing.

Imigaqo yeStainless Steel Pickling kunye nePassivation

Ukumelana nomhlwa kwentsimbi engatyiwayo kubangelwa ikakhulu kukuba umphezulu ugqunywe ngefilim ebhityileyo (malunga ne-1) nm) exineneyo, eyahlula indawo ekrusayo kwaye isebenza njengesithintelo esisisiseko sokhuseleko lwentsimbi engenasici.I-stainless steel passivation ineempawu eziguqukayo kwaye akufanele ithathelwe ingqalelo njengokupheliswa okupheleleyo kokubola.Endaweni yoko, umaleko wesithintelo sokusasazwa kufuneka senziwe, unciphisa kakhulu ireyithi yokusabela kwe-anode.Ngokuqhelekileyo, xa kukho i-agent yokunciphisa (njenge-chloride ion), i-membrane ivame ukulimaza, kwaye xa kukho i-oxidizing agent (efana nomoya), i-membrane inokugcinwa okanye ilungiswe.

Izixhobo zokusebenza zensimbi ezingenasici ezibekwe emoyeni ziya kwenza ifilimu ye-oxide, kodwa ukukhuselwa kwabo akuphelelanga.Ngokuqhelekileyo, ukucocwa ngokucokisekileyo kuqhutyelwa kuqala, kubandakanywa nokuhlamba i-alkaline kunye ne-asidi, elandelwa yi-passivation kunye ne-oxidant ukuqinisekisa ukunyaniseka kunye nokuzinza kwefilimu yokugqithisa.Enye yeenjongo ze-pickling kukudala iimeko ezifanelekileyo zonyango lwe-passivation kunye nokuqinisekisa ukubunjwa kweefilimu eziphezulu ze-passivation.Ukuhlamba i-asidi kubangela ukubola phezu kobuso bensimbi engenasici kunye nobukhulu obuyi-10m.Umsebenzi weekhemikhali wesisombululo se-asidi ubangela ukuba izinga lokuchithwa kwendawo yesiphene libe phezulu kunezinye iindawo zomhlaba.Ke ngoko, ukuhlanjwa kweasidi kunokwenza umhlaba wonke ulungelelane kwaye ukhuphe iingozi ezinokubakho zokubola.Kodwa okona kubaluleke kakhulu, ngokucholwa kweasidi kunye nokupasa, intsimbi kunye neeoksidi zentsimbi zinyibilika ngaphezu kwechromium kunye nechromium oxides, zisusa umaleko ombi wechromium, okukhokelela kubutyebi bechromium kumphezulu wentsimbi engenasici.Ubunakho befilimu etyebileyo yechromium passivation inokufikelela + 1.0V (SCE), ekufutshane nesakhono sesinyithi esixabisekileyo kwaye iphucula ukuzinza kokumelana nokubola.Unyango olwahlukileyo lwe-passivation lunokuchaphazela ukubunjwa kunye nesakhiwo sefilimu, ngaloo ndlela ichaphazela ukuxhathisa kwayo kokubola.Ngokomzekelo, ngonyango lokuguqulwa kwe-electrochemical, ifilimu ye-passivation ingaba nesakhiwo se-multi-layer kwaye senze i-CrO3 okanye i-Cr2O3 kwi-barrier layer, okanye yenze ifilimu ye-glass oxide ukunyusa ukuxhathisa kwe-corrosion yensimbi engenasici.

1.Stainless steel pickling kunye nendlela yokupasa

Indlela yokufakelwa isetyenziselwa iinxalenye ezinokuthi zifakwe kwi-pickling okanye iitanki ze-passivation, kodwa ayifanelekanga ukusetyenziswa kwexesha elide lesisombululo se-pickling kwizixhobo ezinkulu, kunye nokusebenza okuphezulu kwemveliso kunye neendleko eziphantsi;Isixhobo esikhulu somthamo sizaliswe isisombululo se-asidi, kwaye ukusetyenziswa kolwelo lokuntywiliselwa kuphezulu kakhulu.

Ifanelekile kumphezulu wangaphakathi kunye nokusebenza ngokomzimba kwendawo yezixhobo ezinkulu.Iimeko zokusebenza ezimbi kunye nokungakwazi ukubuyisela isisombululo se-asidi.

Indlela yokunamathisela isetyenziswe kwiindawo zokufakela okanye zokugcina, ngokukodwa kwimisebenzi yezandla kwisebe le-welding.Iimeko zabasebenzi zimbi kwaye neendleko zemveliso ziphezulu.

Indlela yokutshiza isetyenziswe kwindawo yofakelo, kunye nomthamo ophantsi wolwelo kudonga lwangaphakathi lwezikhongozeli ezinkulu, ixabiso eliphantsi, kunye nesantya esikhawulezayo, kodwa ifuna ukucwangciswa kompu wokutshiza kunye nenkqubo yokujikeleza.

Indlela yokujikeleza isetyenziselwa izixhobo ezinkulu, ezifana nokutshintsha ubushushu.Ukwakhiwa kwetyhubhu kunye nonyango lwegobolondo lufanelekile, kwaye isisombululo se-asidi singasetyenziswa kwakhona.Ifuna uqhagamshelo lwemibhobho kunye nempompo kwinkqubo yokujikeleza.

Iindlela ze-Electrochemical azinakusetyenziselwa kuphela iinxalenye, kodwa kunye nonyango oluphezulu lwezixhobo ze-site.Itekhnoloji inzima kwaye ifuna unikezelo lwamandla lweDC okanye i-potentiostat.

2.Iinkqubo zePickling kunye ne-passivation

Ukususa igrisi kunye nokucoca ukungcola → Ukuhlamba icandelo lokucocwa kwamanzi → Ukudlula → Ukuhlamba ngamanzi acocekileyo → Ukuvuthela soma

3.Ukunyangwa kwangaphambili ngaphambi kokukhetha kunye nokugqithisa

3.1 Ngokweemfuno zemizobo kunye namaxwebhu enkqubo, yenza i-acid pickling kunye ne-passivation pre-treatment kwi-container steel stainless okanye iinxalenye emva kokuvelisa.

3. Umthungo we-weld kunye ne-welding slag kumacala omabini.Coca ii-splashes, kwaye usebenzise i-petroli okanye i-arhente yokucoca ukususa amabala e-oyile kunye nolunye ukungcola kumphezulu weendawo zokulungisa izitya.

3.3 Xa ususa izinto zangaphandle kumacala omabini e-weld seam, sebenzisa i-brush yensimbi engenastainless steel, ifosholo yensimbi engenasici okanye ivili lokugaya ukuze uzisuse, kwaye uzihlambulule ngamanzi acocekileyo (ngomxholo we-ion ye-chloride engadluli kwi-25mg / l).

Xa i-oil stain inzima, sebenzisa isisombululo se-alkaline se-3-5% sokususa i-oil stain kwaye uhlambulule kakuhle ngamanzi acocekileyo.

3. Ukuqhushumba kwesanti yomatshini kunokususa ulusu lwe-oxide yensimbi engenasici Amalungu asebenzayo ashushu, kwaye isanti kufuneka ibe yisilicon ecocekileyo okanye i-aluminium oxide.

3.6 Ukuphuhlisa imilinganiselo yokhuseleko yokukhethwa kunye nokupasa, kwaye umise izixhobo eziyimfuneko kunye nezixhobo zokukhusela abasebenzi.

4.I-Acid pickling, isisombululo se-passivation kunye nefomula yokunamathisela

4.1 Ifomula yesisombululo sokuhlamba i-asidi: i-nitric acid (1).42) 20%, i-hydrofluoric acid 5%, kwaye intsalela ngamanzi.Oku ngasentla yipesenti yevolumu.

4.2 Ifomula yekhilimu yokucoca i-Acid: i-20 milliliters ye-hydrochloric acid (umlinganiselo 1.19), i-100 milliliters yamanzi, i-30 milliliters ye-nitric acid (umlinganiselo 1.42), kunye ne-150 grams ye-bentonite.

4. Ifomula yesisombululo se-passivation: i-nitric acid (umlinganiselo we-1).42) 5%, i-Potassium dichromate 4g, intsalela ngamanzi.Ipesenti engentla yokuwa, iqondo lokushisa lokufudumala liqondo lokushisa.

4.4 I-passivation paste formula: 30ml nitric acid (concentration 67%), 4g Potassium dichromate, yongeza i-bentonite (100-200 mesh) kwaye ugxobhoze ukunamathisela.

5.I-Acid pickling kunye nokusebenza kwe-passivation

5.1 Kuphela ziikhonteyina okanye iikhomponenti eziye zavavanywa kunye nonyango lwangaphambi kokunyangwa ezinokungena kwi-pickling kunye ne-passivation.

5. I-2 isisombululo se-Acid pickling sisetyenziselwa kakhulu unyango olupheleleyo lweendawo ezincinci ezingaxutywanga, kwaye zinokutshizwa.Ubushushu besisombululo kufuneka bujongwe rhoqo ngemizuzu eyi-10 kwiqondo lobushushu le-21-60 ℃ de kubekho iyunifomu emhlophe ye-acid etching finish.

5.3 I-Pickling Paste I-Pickling ifanele ubukhulu becala kwizikhongozeli ezinkulu okanye ukusetyenzwa kwendawo.Kwiqondo lobushushu begumbi, coca ngokulinganayo ucolo lokuchola kwisixhobo (malunga ne-2-3mm ubukhulu), yiyeke iyure enye, uze emva koko uthambise ngobunono ngamanzi okanye ibrashi yocingo engenastainless de kuvele iyunifomu emhlophe ye-acid etching.

5.4 Isisombululo sePassivation sifanelekile ikakhulu kunyango olupheleleyo lwezikhongozeli ezincinci okanye iinxalenye, kwaye zinokuntywiliselwa okanye zitshizwe.Xa ubushushu besisombululo bungama-48-60 ℃, jonga yonke imizuzu engama-20, kwaye xa iqondo lobushushu lesisombululo lingama-21-47 ℃, jonga iyure nganye kude kube yifilim ye-passivation efanayo kumphezulu.

5.5 I-Passivation paste ifaneleka ikakhulu kwizikhongozeli ezinkulu okanye ukusetyenzwa kwendawo.Isetyenziswe ngokulinganayo kumphezulu wesitya esikhethiweyo (malunga ne-2-3mm) kwindawo yokushisa kunye nokuhlolwa kweyure eli-1 kude kube yifilimu ye-passivation efanayo phezu komhlaba.

5.6 I-Acid pickling kunye ne-passivation containers okanye iinxalenye kufuneka zihlanjululwe ngamanzi acocekileyo phezu komhlaba., Sebenzisa iphepha lokuvavanya i-acidic litmus ukuvavanya nayiphi na indawo yendawo ehlanjiweyo, ukuze uhlambe umphezulu ngamanzi anexabiso le-pH phakathi kwe-6.5 kunye ne-7.5; uze wosule okanye uvuthuze wome ngomoya ocinezelweyo.

5.7.Emva kokukhetha kunye nokugqithisa, akuvumelekanga ukukrazula ifilimu ye-passivation xa uphatha, uphakamisa, kwaye ugcina izitya kunye neengxenye.

Ixesha lokuposa: Aug-08-2023