SAE8620H Steel Round Bar /GB 20CrNiMo Steel bar

Iimbonakalo

Intsimbi ye-8620 ye-alloy yenziwe (ngokwehla komyalelo wepesenti) isinyithi, i-carbon, i-silicon, i-molybdenum, i-manganese, i-nickel, i-chromium, isulfure kunye ne-phosphorus.Ezi zinto zezithako kufuneka zibe ngaphakathi kweepesenti ezithile zobunzima ukwenza i-8620 alloy.Kunconywa ukuba insimbi iqiniswe yi-carburization elandelwa yioli, ngokuchasene namanzi, cima.Inoxinano olufanelekileyo lwentsimbi yealloys kwi-intshi engama-28 nge-intshi nganye, nangona amandla ayo aqinile - ubungakanani bobunzima obunokuthi bubambe ngaphambi kokuphulwa - buphantsi, kwi-536.4 Mpa.I-avareji yamandla e-tensile ye-alloys yensimbi yi-758 ukuya kwi-1882 Mpa.

Xa i-alloy ye-8620 ifakwe ngokufanelekileyo i-carburized - ishushu kwiqondo lokushisa elimiselweyo kwaye emva koko ibonakaliswe kwi-arhente equkethe i-carbon, inkqubo eyongeza i-carbon layer eyongezelelweyo ngaphandle kwentsimbi, ngaloo ndlela iyenza ibe yomelele - isetyenziselwa ukwenza umatshini onjalo. iindawo njengeegiya, ii-crankshafts, kunye namaringi egiya.I-Carburized 8620 alloy yomelele kwaye yomelele, yiyo loo nto ikhethwa kula malungu.

UMGANGATHO: ASTM A29/A29M-2012

Ukuqulunqwa kweekhemikhali

| Ikhabhoni C | 0.17~0,23 |

| Silicon Si | 0.15~0,35 |

| IManganese uMn | 0.65~0,95 |

| Isulfure S | ≤ 0.025 |

| Phosphorus P | ≤ 0.025 |

| IChromium Cr | 0.35~0,65 |

| Nickel | 0.35-0.65 |

| Ubhedu Cu | ≤ 0.025 |

| Molybdenum Mo | 0.15-0.25 |

Iimpawu zoomatshini

| amandla okuqina σ b (MPa) | ≥980(100) |

| isivuno samandla σ (MPa) | ≥785(80) |

| Ubude δ 5 (%) | ≥9 |

| Ukuncipha kwendawo ψ (%) | ≥40 |

| Amandla empembelelo Akv (J) | ≥ 47 |

| Ixabiso lokuqina kwempembelelo α kv (J/cm2) | ≥59(6) |

| Ukuqina | ≤ 197HB |

| Inkqubo | EAF+LF+VOD+Forged+Heat Treatment(ukhetho) |

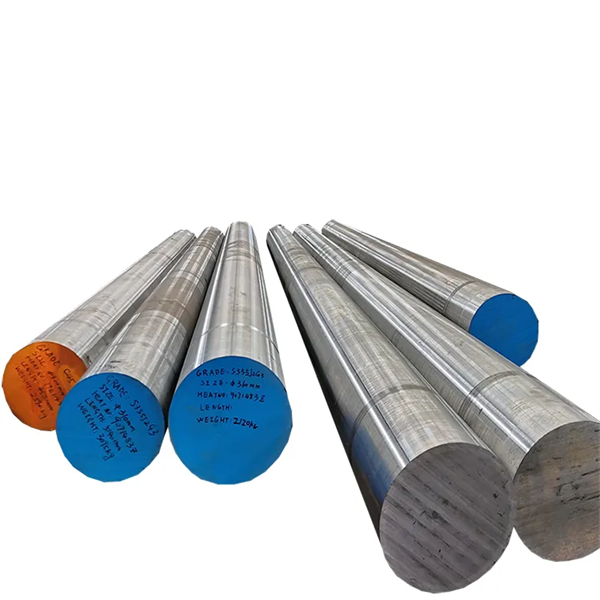

| USIZE UDIDI | |

| Umjikelo | 10mm ukuya 360mm |

| UMPHAKATHI UGQIBELA | Mnyama, Icwecwe (K12), Izotyiweyo ezibandayo, ezijikiweyo & zakhazimliswa (H10, H11), Precision Ground (H9, H8) |

Unyango lobushushu

| Ukusebenza okushushu | 850-1150oC |

| Ukuqina kwetyala | I-HardenngoC ephindwe kabini |

| Carburising | 900-950oC |

| Ukuthambisa okuthambileyo | 650-700oC |

| Ukuqina komphezulu | 800-930oC |

| Ukufudumeza | 150-210oC |

| Uvavanyo lwe-ultrasonic | Ngokutsho kwe-SEP 1921-84 |

Isatifikethi soMgangatho: sikhutshwe ngesiNgesi, ukongeza imimiselo eqhelekileyo, inkqubo yokuvelisa, ipropathi yomatshini (amandla esivuno, amandla okuxinana, ubude nokuqina), umlinganiselo owenziweyo, iziphumo zovavanyo lwe-UT, ubungakanani bengqolowa, iindlela zonyango lobushushu kunye nesampulu. iboniswe kwiSatifikethi soMgangatho.

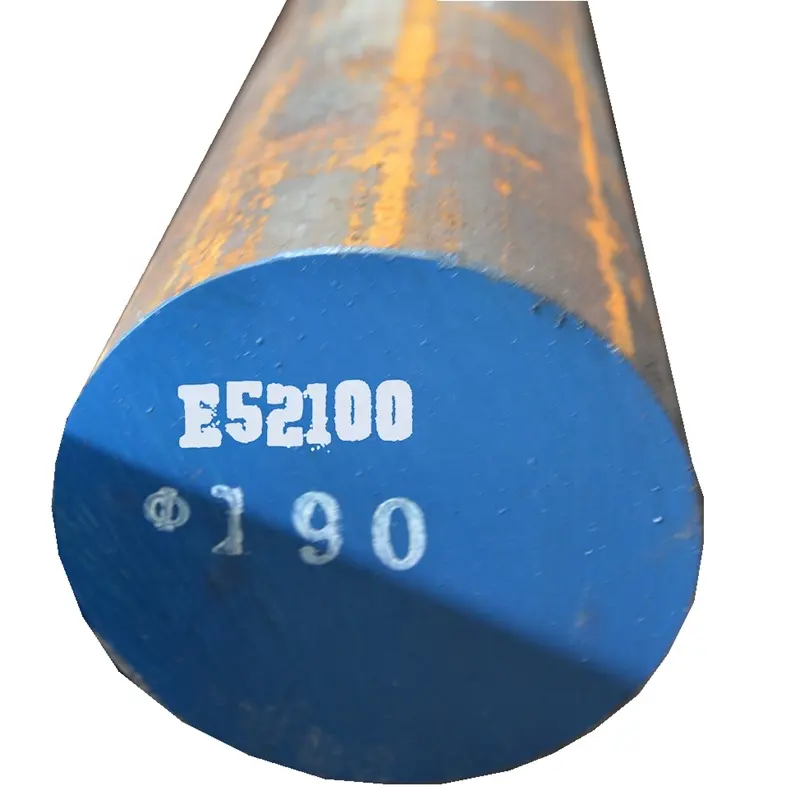

Ukumakishwa: INombolo yobushushu iya kubanda isitampu kwaye ibakala leNsimbi, ububanzi (mm), ubude (mm), kunye nomenzi we-LOGO kunye nobunzima (kg) ipeyintiwe.

Imigangatho Elinganayo

| I-ASTM&AISI&SAE | I-JIS | EN DIN | EN BS | EN NF | ISO | GB |

| 86208620H | I-SNCM220 | 1.6523 | 1.6523 | 1.6523 | ------ | 20CrNiMo |

I-SAE8620H isicelo seBar yentsimbi

Ngokuqhelekileyo isetyenziselwa ukuvelisa iindawo ezibalulekileyo ezinamandla aphezulu kunye neplastiki efanelekileyo, kunye nokwenza iindawo ezibalulekileyo ezineemfuno ezikhethekileyo zokusebenza emva konyango lwe-nitriding:

I-arbors enzima, i-bushings, abalandeli be-Cam, ukunxiba izikhonkwane, iibheringi, i-sprockets, i-gear kunye ne-shafts, i-Clutch Dogs, i-Compressor Bolts, i-Extractors, i-Fan Shafts, i-Heavy Duty Gears, i-Pump Shafts, i-Sprockets, i-Tappets, i-Wear Pins, i-Wire Guides njl. Okanye ingasetyenziselwa ukuxinana okuphezulu kwezicelo ezingangcwatywanga kodwa ngokuqiniswa kunye nobushushu.Isetyenziswa kakhulu ngawo onke amacandelo oshishino kumacandelo kunye neeshafti ezifuna ukumelana nokunxiba okuphezulu komphezulu, amandla aphezulu aphezulu kunye neempawu zempembelelo.

Iphakheji

1.Ngeenyanda, ubunzima bomthwalo ngamnye ngaphantsi kweetoni ezi-3, kubangaphandle ezincinciububanzi bar ngeenxa zonke, inyanda nganye kunye 4 - 8 imicu yentsimbi.

I-2.20 yeenyawo zesikhongozeli iqulethe i-dimension, ubude obungaphantsi kwe-6000mm

I-3.40 yeenyawo zesikhongozeli iqulethe i-dimension, ubude obungaphantsi kwe-12000mm

4.Ngenqanawa enkulu, intlawulo yoThutho iphantsi ngomthwalo omninzi, kwaye inkuluiisayizi ezinzima azinakulayishwa kwizikhongozeli ezinokuhanjiswa ngenqanawa ngomthwalo omninzi

Ukuqinisekisa umgangatho

1. Ngokungqongqo ngokweeMfuno

2. Isampuli: Isampuli iyafumaneka.

3. Iimvavanyo: Uvavanyo lwesitshizi setyuwa / uvavanyo lwe-Tensile / i-Eddy yangoku / uvavanyo lokwakheka kweekhemikhali ngokwesicelo sabathengi

4. Isiqinisekiso: IATF16949, ISO9001, SGS njl.

5. EN 10204 3.1 Isiqinisekiso