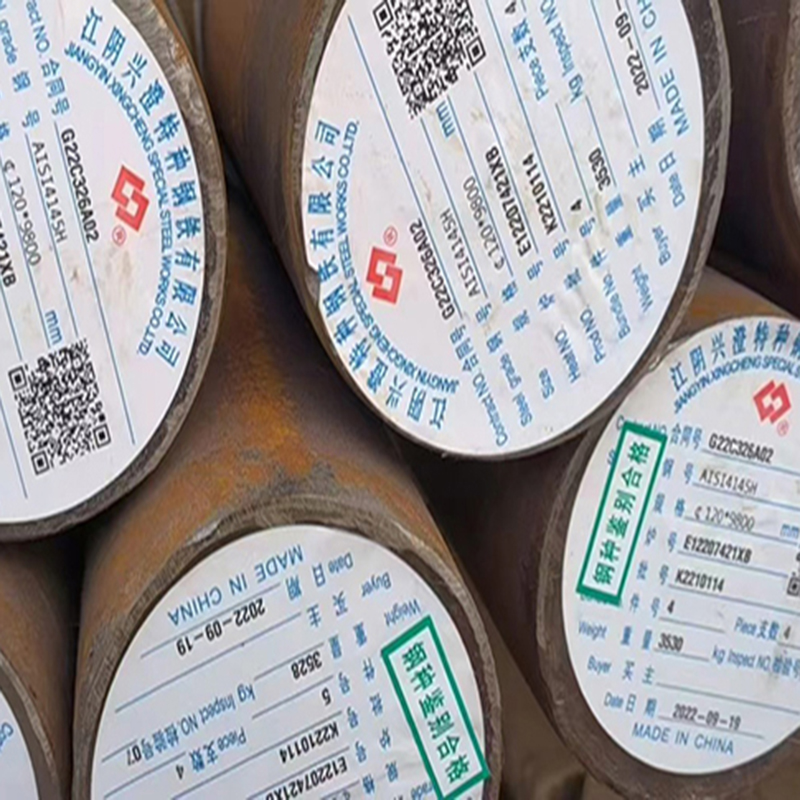

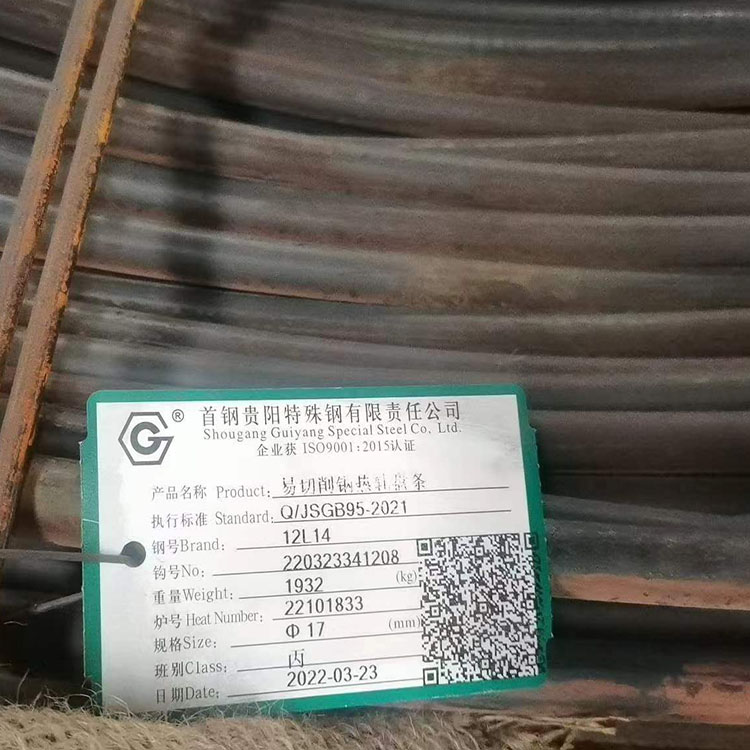

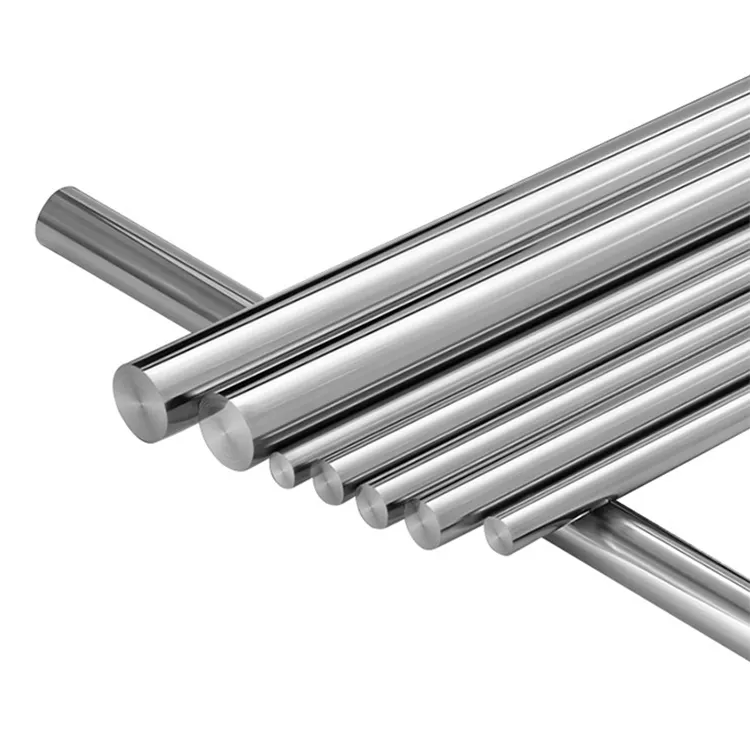

SAE4130 Steel Round Bar AISI 4130 Ingxubevange Steel Bar

Silandela itenet yolawulo "Umgangatho ukhethekile, Uncedo luphezulu, iReputation kuqala", kwaye siyakwenza ngokunyanisekileyo kwaye sabelane ngempumelelo nabo bonke abathengi be-SAE4130 Steel Round Bar AISI 4130 Alloy Steel Bar, Sikwaqhubeka nokuzingela ukuseka ubudlelwane kunye ababoneleli abatsha ukubonelela ngenkqubela phambili kunye nenye indlela ekrelekrele kubathengi bethu abaxabisekileyo.

Silandela iteyithi yolawulo "Umgangatho ukhethekile, Uncedo luphezulu, iReputation kuqala", kwaye siyakwenza ngokunyanisekileyo kwaye sabelane ngempumelelo nabo bonke abathengi.4130 Ibha yentsimbi, Sinethemba lokuba sinokuseka intsebenziswano yexesha elide kunye nabo bonke abathengi.Kwaye sinethemba lokuba singaphucula ukukhuphisana kwaye sifezekise imeko yokuphumelela kunye nabathengi.Samkela ngokunyanisekileyo abathengi abavela kwihlabathi liphela ukuba baqhagamshelane nathi ngayo nantoni na oyifunayo!

Iimbonakalo

4130 4135 4140 4145H imivalo yensimbi yintsimbi ephantsi ye-carbon alloy.Ziyeze-Chrome-Molly alloy equkethe i-chromium kunye ne-molybdenum njengee-agent zokuqinisa.

Ibha yentsimbi eyi-4130 engqukuva inamandla okusebenza, ukuguqulwa okuncinci kokusebenza, kunye nokumelana nokudinwa okugqwesileyo.Kudidi lwentsimbi ephakathi ukuya kokuqina kokuqina.Emva kokunyanga ubushushu, i-4140 inamandla amahle kunye nezixhobo ezibanzi zoomatshini, ubuchule benkqubo elungileyo kunye nesivuno esikhulu.Ubushushu benkonzo bungama-427 degrees celcius.

I-4140 inamandla aphezulu, amandla okuqina, ukuqina, kunye nokuguqulwa ngexesha lokucima.Inamandla aphezulu okurhubuluza kunye namandla okunyamezela kumaqondo obushushu aphezulu.Isetyenziselwa ukuvelisa i-forgings efuna amandla aphezulu kunye namacandelo amakhulu acinyiweyo kunye nobushushu kunentsimbi ye-4135, njengeegiya ezinkulu ze-locomotive traction, i-booster transmission gears, i-axles yangasemva, ii-axles zokudibanisa kunye neziqeshana zasentwasahlobo ezilayishwe kakhulu.

Inkcazo

| Igama lemveliso | AISI ASTM 4130 4135 4140 Intsimbi yentsimbi Bar | |

| Izinto eziphathekayo | I-ASTM | 4130,4135 4140,4145H |

| I-DIN | 1.7218 1.7225 1.7220 | |

| GB | 30CrMo 35CrMO 42CrMo | |

| Umgangatho | GB/T799, ASTM A29, A108, A321, A575, BS970, DIN1652, JIS G4051 | |

| OD | 6mm ukuya 600mm | |

| Umphezulu | Ipeyintiwe emnyama, iBare, ipholishiwe, iPlated ngeChrome | |

| Iinkcukacha | Ibha engqukuva | 8mm ~ 800mm |

| Ibha ye-engile | 3mm*20mm*20mm~12mm*800mm*800mm | |

| Ibar yesikwere | 4mm*4mm~100mm*100mm | |

| Ibha ecaba | 2*10mm~100*500mm | |

| Hexagonal | 4mm ~ 800mm | |

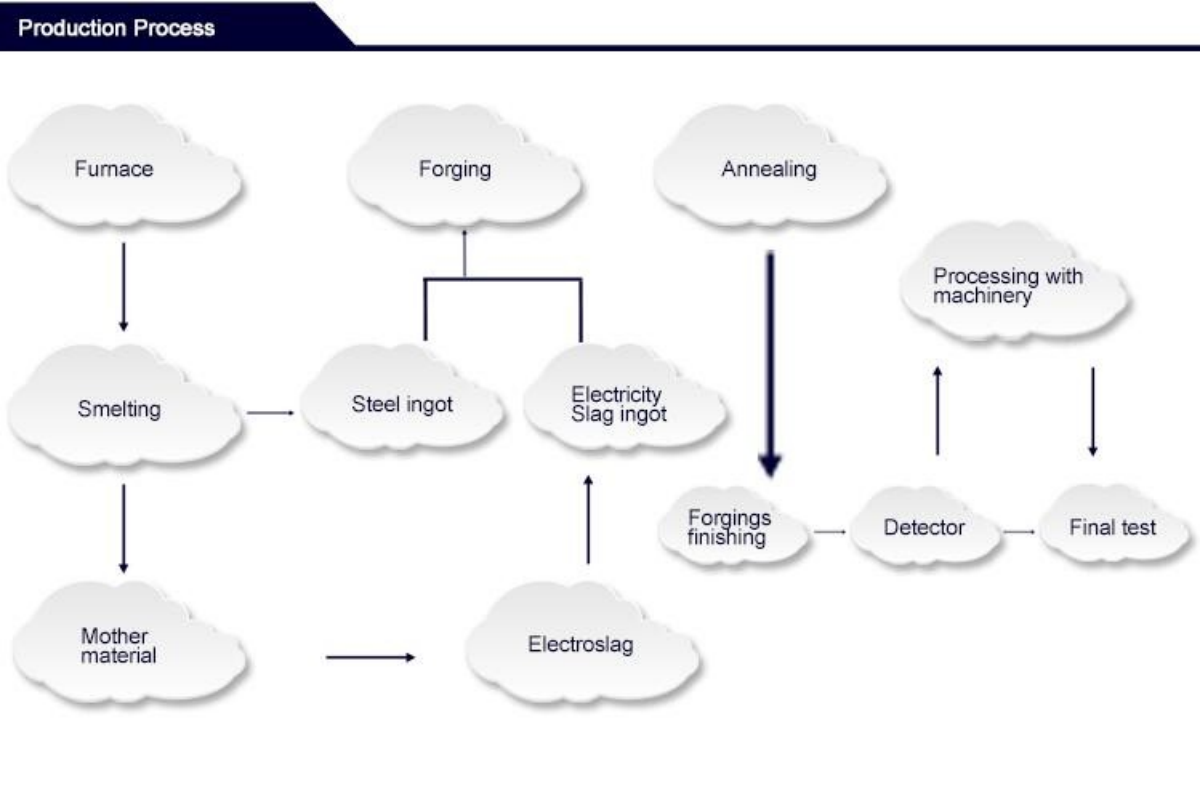

| Inkqubo | Iziko lombane elinyibilikisiweyo, lenziwe ngenkohliso kwaye lifakwe intsimbi, ibha engqukuva ejikiweyo. | |

| Ukuqina: | I-HBS 217Max (Yahlukile kunyango lobushushu) | |

| Uvavanyo lwe-UT | SEP 1921/84/2 C/c iklasi. | |

| Ukunyamezelana | I-Dia -0/+ 0~5mm, Ukutyeba -0/+ 0~5mm, Ububanzi: -0/+ 0~10mm. | |

| Ubude | 2m, 4m, 5.8m, 6m, 11.8m, 12m okanye njengoko kufuneka. | |

| Iphakheji | Ukupakishwa kolwandle. | |

| Umgangatho olinganayo owahlukileyo | |||

| AISI | GB | I-DIN | I-JIS |

| 4130 | 30CrMo | 1.7218 | I-SCM420 |

| 4140 | 42CrMo | 1.7225 (42CrMo4) | I-SCM440 |

| 4135 | 35Crmo | 1.7220(34CrMo4) | I-SCM432 |

| 4145H | - | - | - |

Ukuqulunqwa kwemichiza

| Ukwakhiwa kwemichiza (%) | |||||||

| IBanga | C | Si | Mn | P | S | Cr | Mo |

| 4130 | 0.28-0.33 | 0.15-0.35 | 0.40-0.60 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0.25 |

| 4140 | 0.38-0.43 | 0.15-0.35 | 0.75-1.0 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0.25 |

| 4135 | 0.33-0.38 | 0.15-0.35 | 0.75-0.9 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0.25 |

| 4145 | 0.43-0.48 | 0.15-0.35 | 0.75-1.0 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0.25 |

Iipropati zoomatshini

| Iimpawu: |

| I-1.Intsimbi ephantsi ye-alloy equkethe i-molybdenum kunye ne-chromium njenge-agent ezomelezayo; |

| 2.Egqwesileyo kwimbono ye-fusion weldability; |

| 3.I-alloy inokuqiniswa ngonyango lobushushu. |

Ukunyamezelana

| Unikezelo lwemeko |

| 1.Hot rolled |

| 2.Anealed |

| 3.Iqhelekile |

| 4. Cima kwaye Ucaphuke |

Iimeko zonyango lobushushu

1.Annealing: 880℃ Ukupholisa eziko

2.Normalization: 880 ~ 870℃ Ukupholisa umoya

3.Ukuqina: 820 ~ 870℃ Ukupholisa amanzi

4.Ubushushu: 550 ~ 650℃ Ukupholisa ngokukhawuleza

IiPropati zoomatshini zinokufunyanwa ngonyango olwahlukileyo lobushushu.

Iphakheji

1.Ngeenyanda, ubunzima bomthwalo ngamnye ngaphantsi kweetoni ezi-3, kubangaphandle ezincinci

ibha yobubanzi obuyingqukuva, inyanda nganye enezintlu zentsimbi ezi-4 – 8.

I-2.20 yeenyawo zesikhongozeli iqulethe i-dimension, ubude obungaphantsi kwe-6000mm

I-3.40 yeenyawo zesikhongozeli iqulethe i-dimension, ubude obungaphantsi kwe-12000mm

4.Ngenqanawa enkulu, intlawulo yoThutho iphantsi ngomthwalo omninzi, kwaye inkulu

iisayizi ezinzima azinakulayishwa kwizikhongozeli ezinokuhanjiswa ngenqanawa ngomthwalo omninzi

Ukuqinisekisa umgangatho

1.Ngokungqongqo ngokweeMfuno

2. Isampuli: Isampuli iyafumaneka.

3. Iimvavanyo: Uvavanyo lwesitshizi setyuwa / uvavanyo lwe-Tensile / i-Eddy yangoku / uvavanyo lokwakheka kweekhemikhali ngokwesicelo sabathengi

4.Isatifikethi: IATF16949, ISO9001, SGS njl.

5. EN 10204 3.1 Isiqinisekiso

I-SAE4130 intsimbi ejikelezayo yintsimbi yexabiso le-alloy.Umgangatho we-ASTMA29/A29M-04.Uphawu lwasekhaya oluhambelanayo: 30CrMo Olungqameneyo nophawu lwaseJapan: SCM430 (SCM2) oluhambelanayo nophawu lwesiJamani: 34CrMo4 (1.7220)

I-4130 yensimbi yesakhiwo inamandla amakhulu kunye nokuqina, ukuqina okuphezulu, kunye nobukhulu obunzima be-15-70mm kwioli;Amandla e-thermal ensimbi nawo alungile, anamandla okwaneleyo obushushu obuphezulu obungaphantsi kwe-500 ℃, kodwa amandla ayo ayancipha kakhulu kwi-550 ℃;Xa i-alloy element ikumda ophantsi, i-welding ilungile, kodwa xa isondele kumda ophezulu, i-weldability iphakathi, kwaye i-preheating ukuya ngaphezu kwe-175 ℃ iyafuneka phambi kwe-welding;Isinyithi sinokusebenza kakuhle kunye neplastiki ephakathi ngexesha lokuguqulwa okubandayo;Ngexesha lonyango lobushushu, kukho ukuvutha komsindo ofanayo kuluhlu lwe-300-350 ℃;Kukho umkhuba wokwenza amabala amhlophe.

I-SAE4130 isetyenziswa ikakhulu kumashishini okuvelisa oomatshini abaphakathi ukwenza iinxalenye ezicinyiweyo nezipholileyo ezinamacandelwana amakhulu anqamlezayo asebenza phantsi kweemeko zoxinzelelo oluphezulu, ezinje ngeeshafti, iintambo zokuphotha, kunye namavili okulawula umthwalo ophezulu, iibholiti, iibholiti zentloko ezimbini, iigiya, njl.Isetyenziswa kwishishini lemichiza ukwenza iinxalenye ezidityanisiweyo, izakhiwo ezidityanisiweyo ezenziwe ngamacwecwe kunye nemibhobho, kunye nemibhobho yoxinzelelo oluphezulu enobushushu obungagqithiyo kuma-250 ℃ esebenza kwindawo equlethe initrogen kunye nehydrogen;Kwishishini lemveliso yeeinjini zomphunga kunye nezibiyitha, isetyenziselwa ukwenza izinto zokuqhobosha ezisebenza ngaphantsi kwe 450 ℃, iiflange kunye nezigqubuthelo zeflange phantsi koxinzelelo oluphezulu olungaphantsi kwama-500 ℃.