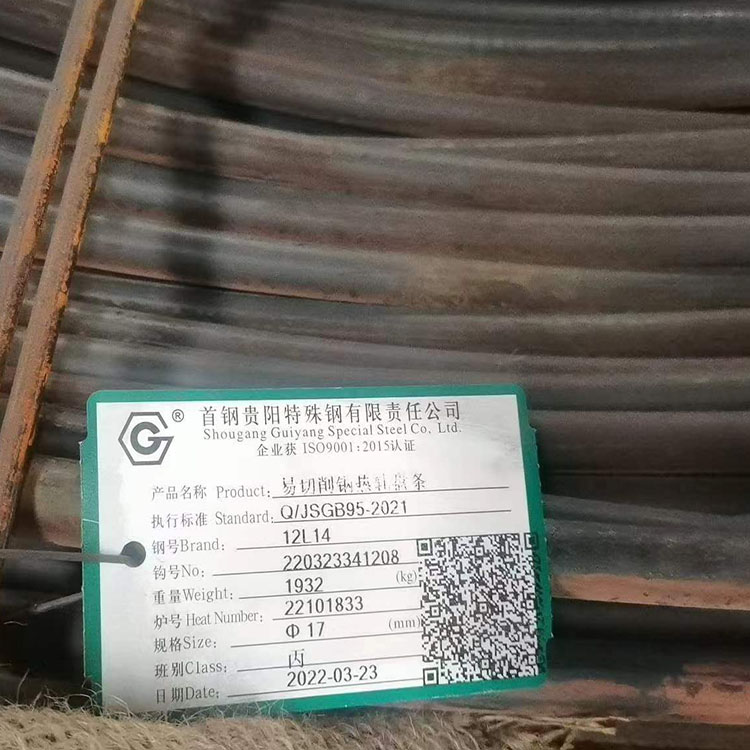

Umvelisi we-SAE 1215 / AISI 1215 Cold Drawn Free Cutting Steel Round Bars

Ishishini lethu ligxininisa kulo lonke umgaqo-nkqubo womgangatho “wemveliso ekumgangatho ophezulu isiseko sokuphila kombutho;ukwaneliseka kwabathengi kuya kuba yindawo yokujonga kunye nesiphelo senkampani;Uphuculo oluzingisileyo kukusukela ngonaphakade abasebenzi” kunye nenjongo engaguqukiyo “yodumo kuqala, umthengi kuqala” kuMvelisi we-SAE 1215 / AISI 1215 Cold Drawn Free Cutting Steel Round Bars, Kuba sihlala kulo mgca malunga ne-10 iminyaka.Sifumene inkxaso yababoneleli abangcono kumgangatho kunye nexabiso.Kwaye besibakhuphele ngaphandle abaxhasi abakumgangatho ophantsi.Ngoku iifektri ezininzi ze-OEM zisebenzisana nathi.

Ishishini lethu ligxininisa kulo lonke umgaqo-nkqubo womgangatho “wemveliso ekumgangatho ophezulu isiseko sokuphila kombutho;ukwaneliseka kwabathengi kuya kuba yindawo yokujonga kunye nesiphelo senkampani;Uphuculo oluzingisileyo kusukelo lwanaphakade lwabasebenzi” kunye nenjongo engaguqukiyo “yodumo kuqala, umthengi kuqala”1215 ibha yentsimbi, aisi1215 ebandayo itsalwa simahla ukusika ibha bar, sinomgca opheleleyo wemveliso, umgca wokuhlanganisa, inkqubo yokulawula umgangatho, kwaye okona kubaluleke kakhulu, sinobuchwephesha bamalungelo awodwa omenzi wechiza kunye namava obugcisa neqela lemveliso, iqela lenkonzo yokuthengisa yeengcali.Ngazo zonke ezi zibonelelo, siza kudala “uphawu lwamazwe ngamazwe lwenayiloni monofilaments”, kwaye sisasaze iimpahla zethu kuzo zonke iikona zehlabathi.Besisoloko sihamba kwaye sizama konke okusemandleni ethu ukunceda abathengi bethu.

Iinkcukacha zeMveliso

I-ASTM AISI 1212 1215 1140 1144 Ibha yentsimbi yokusika yasimahla yintsimbi ephezulu yesulfure ephantsi-ephantsi yekhabhoni, enentsebenzo engcono yokusika xa kuthelekiswa ne-10# 25# 35# 45# intsimbi, i-ASTM 1212 1215 1140 1144 inako ukwandisa ubomi besixhobo amaxesha, ukwandisa imveliso nge-30%, kwaye unamandla aphezulu kunye nobunzima.

Umgangatho: ASTM A29/A29M-04

I-ASTM AISI 1212 1215 1140 1144 Intsimbi yokusika yasimahla zizinto zetsimbi ezinokumelana nokunxiba kakuhle kunye nokuchasana nempembelelo.Intsimbi yokusika yasimahla isetyenziswa ngokuqhelekileyo ekuveliseni amacandelo, izixhobo, okanye ezinye izixhobo, ezinjengamacangca esixhobo somatshini, i-valve body clamps, njl. njl inokusetyenziswa ngokubanzi kwiindawo ezahlukeneyo zokulungisa oomatshini.I-ASTM1212 1215 1140 1144 intsimbi yokusika yasimahla ibonisa ukuxhathisa okugqwesileyo kokunxiba kumaqondo obushushu aphezulu, ngelixa kumaqondo obushushu asezantsi ibonisa amandla alungileyo kunye namandla angaphandle.Ukongeza, intsimbi inamandla aphezulu kakhulu kwaye inokumelana nemithwalo enzima.I-ASTM1212 1215 1140 1144 intsimbi yokusika yasimahla inokumelana nobushushu kwaye ayiyi kutshisa naxa ishushu kwidangatye.

Iiparamitha

| Ubungakanani | Round Bar | I-Dia 6-1200mm |

| Ipleyiti/Flethi/Ibhlokhi | Ukutyeba: 6mm-500mm | |

| Ububanzi: 20mm-1000mm | ||

| Unyango lobushushu | Iqhelekile ;I-Anealed;Ucinywe ;Unomsindo | |

| Uhlobo | Ukutsalwa okubandayo/kushushu kuqengqeleka | |

| Imeko yomphezulu | Mnyama;Ixotshiwe;Ikhazimlisiwe;Yenziwe ngoomatshini;Igayiwe;Ijikiwe;Milled | |

| Imeko yonikezelo | Yenziwe;Ishushu esongwayo;Kuyabanda | |

| Uvavanyo | Amandla okuqina, amandla okuvelisa, ukongezwa, indawo yokunciphisa, ixabiso lempembelelo, ubulukhuni, ubungakanani beenkozo, uvavanyo lwe-ultrasonic, ukuhlolwa kwe-US, uvavanyo lwamasuntswana omlingo, njl. | |

| Isicelo | I-ASTM 1212 1215 1140 1144 ifanelekile kumatshini wokwenza izinto ezifuna ubulukhuni obuphezulu, njenge-lead screw, intonga epholisiweyo, i-rack kunye ne-spline shaft, njl. | |

| Ukwakhiwa kwemichiza (%) | ||||

| IBanga | C | Mn | P | S |

| 1212 | ≤0.13 | 0.70-1.00 | 0.07-0.12 | 0.16-0.23 |

| 1215 | ≤0.09 | 0.75-1.05 | 0.04-0.09 | 0.24-0.33 |

| 1140 | 0.37-0.44 | 0.7-1.0 | ≤0.04 | 0.08-0.13 |

| 1144 | 0.40-0.48 | 1.35-1.65 | ≤0.04 | 0.24-0.33 |

| Ukulingana nemigangatho eyahlukeneyo | ||||

| I-AISI/ASTM | GB | EN10087 | I-JIS | I-DIN |

| 1212 | Y12 | - | SUM21 | - |

| 1215 | Y15 | 11SMn30 | - | - |

| 1140 | Y35 | - | SUM41 | - |

| 1144 | Y40Mn | 38SMn28 | SUM43 | 44Mn28 |

Ipakethe&Ukuthumela ngenqanawe

Ukuqinisekisa umgangatho

1.Ngokungqongqo ngokweeMfuno

2.Isampuli: Isampuli iyafumaneka.

3. Iimvavanyo: Uvavanyo lwesitshizi setyuwa / uvavanyo lwe-Tensile / i-Eddy yangoku / uvavanyo lokwakheka kweekhemikhali ngokwesicelo sabathengi

4.Isatifikethi: IATF16949, ISO9001, SGS njl.

5. EN 10204 3.1 Isiqinisekiso

I-SAE / AISI 1215 ibha yensimbi yokusika yamahhala luhlobo lwentsimbi yokusika ngokulula kunye nokusebenza kakuhle kwe-machining, esetyenziswa ngokubanzi kumacandelo omatshini, i-shafts, izixhobo kunye nezinye iindawo.

Amacandelo aphambili e-1215 yensimbi yokusika i-carbon, i-manganese, kunye nesulfure, enomxholo ophezulu wesulfure, enokuphucula ukusebenza kwensimbi.Ubunzima bentsimbi ye-1215 bujikeleze i-135-180HBW, kunye nokusebenza kakuhle kunye nomphezulu owenziwe ngomatshini.Ubunzima obuthile bentsimbi ye-1215 yi-7.85g/cm ³, Iyafana nentsimbi eqhelekileyo.

I-1215 insimbi isetyenziselwa ubukhulu becala kumacandelo okuvelisa kunye namacandelo, njengama-bolts, amantongomane, izikhonkwane, njl njlUkongeza, intsimbi ye-1215 ingasetyenziselwa ukuvelisa izinto ezinoomatshini kunye nezakhiwo zamandla aphezulu.

Itekhnoloji yokucubungula ye-1215 yensimbi ibandakanya ikakhulu iindlela ezimbini: unyango lobushushu kunye nokulungiswa okubandayo.Indlela yokunyanga ukushisa iquka ukucima kunye nokufudumala, okunokuphucula ubunzima kunye namandla entsimbi.Iindlela zokusebenza ezibandayo ziquka ukunweba, ukunyathela, ukucheba, njl., ezinokwenza intsimbi ibe namandla aphezulu kunye nokuqina.Intsimbi ye-1215 nayo inokusebenza kakuhle kwe-welding kwaye inokudityaniswa kusetyenziswa iindlela ezifana ne-argon arc welding kunye ne-resistance welding.Kunyango lomphezulu, intsimbi ye-1215 inokunyangwa ngeendlela ezinje nge-pickling kunye ne-electroplating ukuphucula ukuguda komphezulu kunye nokumelana nokubola.

Iinzuzo eziphambili ze-1215 zensimbi zilula ukusetyenzwa, ixabiso eliphantsi, amandla aphezulu, kunye nokumelana nokunxiba kakuhle, okwenza ukuba ilungele ukuveliswa kobuninzi.Nangona kunjalo, intsimbi ye-1215 inomxholo ophezulu wesulfure kwaye ixhomekeke kwi-hydrogen embrittlement.Kwangaxeshanye, iqhelekile ukuthomalalisa kunye nokuthamba kumaqondo obushushu aphezulu, okwenza ukuba ingafanelanga ukusetyenziswa kwiindawo ezinzima ezifana nobushushu obuphezulu kunye noxinzelelo.