AISI SAE 4130 4140 4145H Steel Round Bar Hollow Rod

Iimbonakalo

4130 4135 4140 4145H imivalo yensimbi yintsimbi ephantsi ye-carbon alloy.Ziyeze-Chrome-Molly alloy equkethe i-chromium kunye ne-molybdenum njengee-agent zokuqinisa.

Ibha yentsimbi eyi-4130 engqukuva inamandla okusebenza, ukuguqulwa okuncinci kokusebenza, kunye nokumelana nokudinwa okugqwesileyo.Kudidi lwentsimbi ephakathi ukuya kokuqina kokuqina.Emva kokunyanga ubushushu, i-4140 inamandla amahle kunye nezixhobo ezibanzi zoomatshini, ubuchule benkqubo elungileyo kunye nesivuno esikhulu.Ubushushu benkonzo bungama-427 degrees celcius.

I-4140 inamandla aphezulu, amandla okuqina, ukuqina, kunye nokuguqulwa ngexesha lokucima.Inamandla aphezulu okurhubuluza kunye namandla okunyamezela kumaqondo obushushu aphezulu.Isetyenziselwa ukuvelisa i-forgings efuna amandla aphezulu kunye namacandelo amakhulu acinyiweyo kunye nobushushu kunentsimbi ye-4135, njengeegiya ezinkulu ze-locomotive traction, i-booster transmission gears, i-axles yangasemva, ii-axles zokudibanisa kunye neziqeshana zasentwasahlobo ezilayishwe kakhulu.

Inkcazo

| Igama lemveliso | AISI ASTM 4130 4135 4140 Intsimbi yentsimbi Bar | |

| Izinto eziphathekayo | I-ASTM | 4130,4135 4140,4145H |

| I-DIN | 1.7218 1.7225 1.7220 | |

| GB | 30CrMo 35CrMO 42CrMo | |

| Umgangatho | GB/T799, ASTM A29, A108, A321, A575, BS970, DIN1652, JIS G4051 | |

| OD | 6mm ukuya 600mm | |

| Umphezulu | Ipeyintiwe emnyama, iBare, ipholishiwe, iPlated ngeChrome | |

| Iinkcukacha | Ibha engqukuva | 8mm ~ 800mm |

| Ibha ye-engile | 3mm*20mm*20mm~12mm*800mm*800mm | |

| Ibar yesikwere | 4mm*4mm~100mm*100mm | |

| Ibha ecaba | 2*10mm~100*500mm | |

| Hexagonal | 4mm ~ 800mm | |

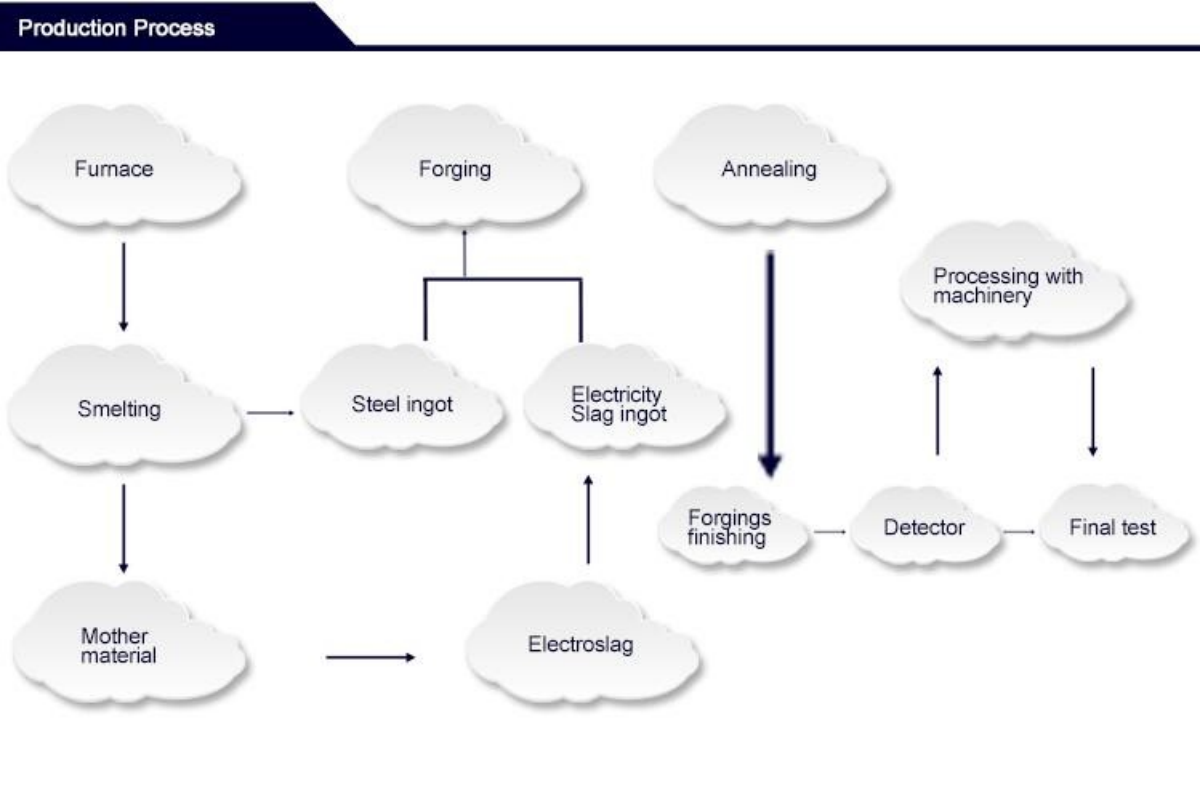

| Inkqubo | Iziko lombane elinyibilikisiweyo, lenziwe ngenkohliso kwaye lifakwe intsimbi, ibha engqukuva ejikiweyo. | |

| Ukuqina: | I-HBS 217Max (Yahlukile kunyango lobushushu) | |

| Uvavanyo lwe-UT | SEP 1921/84/2 C/c iklasi. | |

| Ukunyamezelana | I-Dia -0/+ 0~5mm, Ukutyeba -0/+ 0~5mm, Ububanzi: -0/+ 0~10mm. | |

| Ubude | 2m, 4m, 5.8m, 6m, 11.8m, 12m okanye njengoko kufuneka. | |

| Iphakheji | Ukupakishwa kolwandle. | |

| Umgangatho olinganayo owahlukileyo | |||

| AISI | GB | I-DIN | I-JIS |

| 4130 | 30CrMo | 1.7218 | I-SCM420 |

| 4140 | 42CrMo | 1.7225 (42CrMo4) | I-SCM440 |

| 4135 | 35Crmo | 1.7220(34CrMo4) | I-SCM432 |

| 4145H | - | - | - |

Ukuqulunqwa kwemichiza

| Ukwakhiwa kwemichiza (%) | |||||||

| IBanga | C | Si | Mn | P | S | Cr | Mo |

| 4130 | 0.28-0.33 | 0.15-0.35 | 0.40-0.60 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0.25 |

| 4140 | 0.38-0.43 | 0.15-0.35 | 0.75-1.0 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0.25 |

| 4135 | 0.33-0.38 | 0.15-0.35 | 0.75-0.9 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0.25 |

| 4145 | 0.43-0.48 | 0.15-0.35 | 0.75-1.0 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0.25 |

Iipropati zoomatshini

| Iimpawu: |

| I-1.Intsimbi ephantsi ye-alloy equkethe i-molybdenum kunye ne-chromium njenge-agent ezomelezayo; |

| 2.Egqwesileyo kwimbono ye-fusion weldability; |

| 3.I-alloy inokuqiniswa ngonyango lobushushu. |

Ukunyamezelana

| Unikezelo lwemeko |

| 1.Hot rolled |

| 2.Anealed |

| 3.Iqhelekile |

| 4. Cima kwaye Ucaphuke |

Iimeko zonyango lobushushu

1.Annealing: 880℃ Ukupholisa eziko

2.Normalization: 880 ~ 870℃ Ukupholisa umoya

3.Ukuqina: 820 ~ 870℃ Ukupholisa amanzi

4.Ubushushu: 550 ~ 650℃ Ukupholisa ngokukhawuleza

IiPropati zoomatshini zinokufunyanwa ngonyango olwahlukileyo lobushushu.

Iphakheji

1.Ngeenyanda, ubunzima bomthwalo ngamnye ngaphantsi kweetoni ezi-3, kubangaphandle ezincinci

ububanzi bar ngeenxa zonke, inyanda nganye kunye 4 - 8 imicu yentsimbi.

I-2.20 yeenyawo zesikhongozeli iqulethe i-dimension, ubude obungaphantsi kwe-6000mm

I-3.40 yeenyawo zesikhongozeli iqulethe i-dimension, ubude obungaphantsi kwe-12000mm

4.Ngenqanawa enkulu, intlawulo yoThutho iphantsi ngomthwalo omninzi, kwaye inkulu

iisayizi ezinzima azinakulayishwa kwizikhongozeli ezinokuhanjiswa ngenqanawa ngomthwalo omninzi

Ukuqinisekisa umgangatho

1.Ngokungqongqo ngokweeMfuno

2. Isampuli: Isampuli iyafumaneka.

3. Iimvavanyo: Uvavanyo lwesitshizi setyuwa / uvavanyo lwe-Tensile / i-Eddy yangoku / uvavanyo lokwakheka kweekhemikhali ngokwesicelo sabathengi

4.Isatifikethi: IATF16949, ISO9001, SGS njl.

5. EN 10204 3.1 Isiqinisekiso